Get ready for your Custom Canvas Structures appointment

6 Quick Points that may help

By taking just a few short minutes we can help you get educated and ready to incorporate awnings into your home or business and start seeing the benefits of both their form and function. By reading the following five sections below you will have a better understanding of awnings in general and be armed with a few of the why and why not. Awnings are one of the single easiest methods of both protecting and beautifying your home or building. For thirty years plus we have been working with customers in the Tampa Bay area and further to add just the right amount of color, escape the heat or protect those beautiful French doors that always seem to be rotting away.

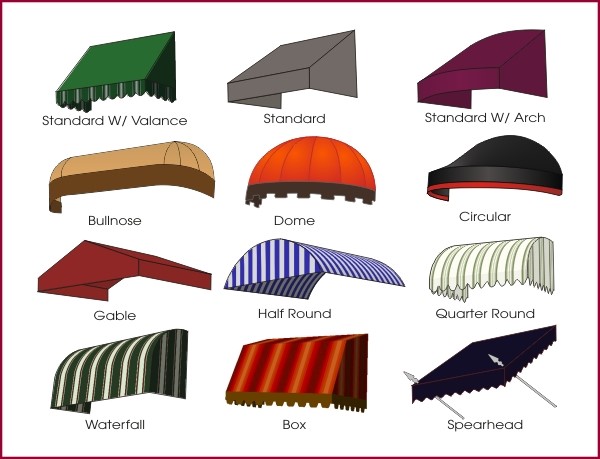

First off you are going to want to ask yourself what type of awning you are looking for. Below are just a few of the available awning types.

For more ideas take a look at our gallery pages for:

Commercial, Residential, Industrial, Sports and Specialty, Tension Shade Canopied, and sails

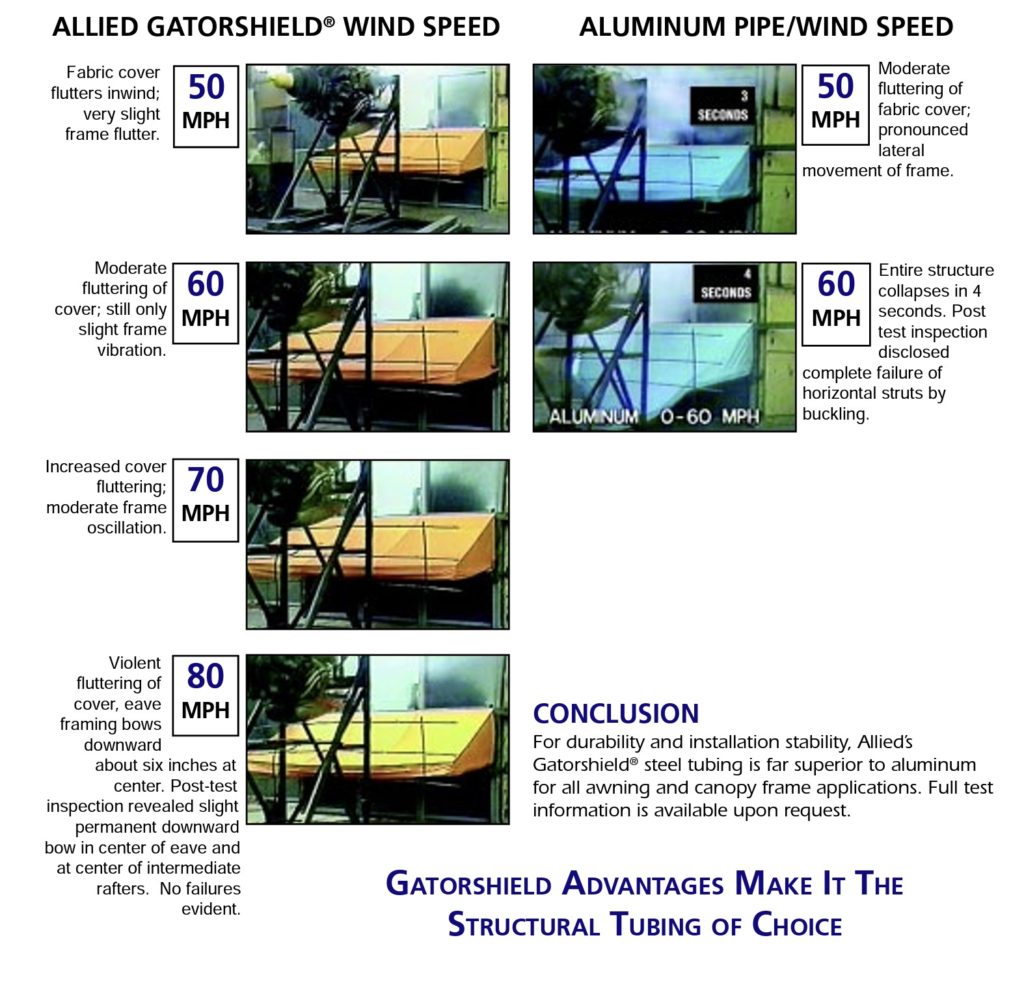

The second would be what type of frame. Aluminum or galvanized steel frames. There are pros and cons to each. Sure, Aluminum will corrode less over time than Steel might but that can come with a price. That price is strength. In Florida’s 2017 Hurricane Michael, 90 Percent or more of the Awnings Frames that were damaged were aluminum. Aluminum frames are simply weaker than Steel and whether it’s a bad storm or a teenager wanting to knock out a few pullups, aluminum is going to bend far more easily than steel. Custom Canvas or CCS for short has Galvanized Steel frames over boat docks, and over salt water that has been there in good shape for 25-plus years. We also apply a Zinc coating on all of the welds which further prolongs the life of the awning frame. Our Galvanized steel frame is built from Gatorshield® manufactured by Allied Tube & Conduit it is a patented triple-layer Flo-Coat® rust and corrosion-resistant product that has shown itself to be the best over the long haul versus all competitive product offerings.

I would like to encourage you to (click here) and look specifically at page three of the PDF document that outlines the strength differences between Aluminum and Gatorshield. In the results, some of which I included below, seen there you will see how the Aluminum frame completely failed at 60 miles per hour whereas the Steel frames held strong.

When rust and corrosion protection is needed …….. Gatorshield® is the best! Now don’t getus wrong, Aluminum has its place, and where the customer wants it we typically don’t charge any more for an Aluminum frame than we do a galvanized Steel one. They are a good choice in certain applications and mandatory when dealing with staple awnings, but we will get into that next. It has simply been our experience of more than 30 years in the business that our steel frames have had less damage and has held up better than Aluminum Frames. We have recovered awnings 2 and three times made from steel with minimal repairs needed to be made to the framing. But again, the important thing to note is Steel or Aluminum, CCS has the knowledge and expertise to give the customer what they want and will talk through these options with you to ensure you’re getting exactly what you want.

Third, you might ask yourself, should I get a laced fabric awning or a staple stitched awning? This is one of those pay me now or pay me later products. This all has to do with how the awning fabric is attached to the frame. CCS’s preferred method of attaching the fabric to the frame is via what’s called a lace bar. This allows the awning fabric to be securely slid into a rope rail at the top of the awing and then pulled down and laced tight to the frame with rope.

A staple fabric system uses a two-part system where the fabric is first pulled down over the frame, then it is stapled into the aluminum extrusion, and a plastic strip is beaten with a specialty tool down into the groove over top of the fabric and staples. Staple awnings have their strengths and weaknesses but originally staple awnings were essentially the sign industries way into the awning world. They gave sign companies a method to build awnings that required far less craftsmanship or expertise as there is little to no sewing involved.

When are stapled awnings a problem? Well, first off they must be made out of Aluminum, which again is not a terrible thing but we have already addressed that. The real issue comes the day that you would like to paint your house and change the color of the awning fabric or a tree branch pokes a hole in it. See, if you have a staple awing you are almost 100 percent of the time going to have to remove the frame, and bring it back to the shop, all of the staples have to be pulled out of the frame and that fabric is redone. Then take the frame and fabric back to be installed. Also, if the fabric relaxes at all, over time, there is no tensioning ability built-in like a laced awning frame has.

If you have a laced awning, typically the old fabric can be removed for a pattern or the frame surveyed for key measurements, and new fabric can be brought out and installed in place. Not to mention when you know a big storm is on its way to your area, within just a few minutes you can use a pair of scissors to cut the rope and pull the fabric out of the track. When Hurricane Michael came through we were called out to remove hundreds of awnings in the area and not one of those awnings got damaged by the storm. Now, there seems always to be a second side to a coin, and staple awnings are no different. In certain applications, a staple awing might be just the right product for the look or configuration of the project. Although they come with some disadvantages they can sometimes be the perfect solution for particular projects and designs.

Fourth, Let’s talk about Fabric. There are tons of fabric manufacturers out there and although we would not say ever or never we do primarily only use Sunbrella Marine/Awning grade acrylic woven fabrics, Patio 500 Vinyl, Weblon, or Polytex shade fabrics.

Sunbrella Marine/Awning Fabrics (CLICK HERE TO SEE THESE FABRICS) To see a digital sample card (Click Here) – This really is the go-to fabric mostly for homeowners. It is softer looking than vinyl and, well it is probably the most familiar name on the market. As wonderful as Sunbrella is it does have a few drawbacks. It’s not considered a waterproof material. As with pretty much any woven material, it can and it will leak some, especially when there is not enough slope or pitch built into the awning. Another big one is, standard Sunbrella fabrics are not fire-resistant. That said, if you’re in the market for an awning for your commercial building it is quite likely they will want a fire certification when you try and get a permit, and without jumping through some hoops and potentially voiding the warranty from Sunbrella you simply can’t use it.

Patio 500 Vinyl. (CLICK HERE TO SEE THESE FABRICS) – To see a digital sample card (Click Here) . So Patio 500 vinyl is a 100 percent waterproof product. It does not have to have a whole lot of slope to be effective and it lasts a really long time. It also has fire-resistant properties and getting a fire cert is no problem for this material. The con is that some folks tend to think it is a bit too industrial-looking. Although there are a few, albeit much more expensive, vinyl products out there that have a canvas look to them. One such material that we use is called Natura. Weblon is much the same as Patio 500 with the main difference being that, whereas Weblon can be decorated with adhesive-backed graphics for storefront signage, Patio 500 cannot.

Polytex is a fabulous shade sail and tension structure-capable fabric that has high durability and excellent span ability.

Fifth, we would like to say a little something about hardware. Some folks ask if we use stainless steel fasteners, which at first seems like the way to go, but remember the whole pros and cons of things. Stainless concrete screws, for instance, will without a doubt corrode a little bit less than the standard Blue Climseal and zinc-coated Tapcons but again that comes with a price. That price is when you would like to take that awing frame down to paint the house or for some other reason. Stainless, once installed scalds and will often snap off when you attempt to remove them, whereas the standard Blue Tapcons will typically come out. We do see some more corrosion with a standard Tapcon but that is always better than them snapping off in the wall and having to create more penetrations into the frame and wall. We can and do at the customer’s request use Stainless hardware and we are happy to discuss with you these options.

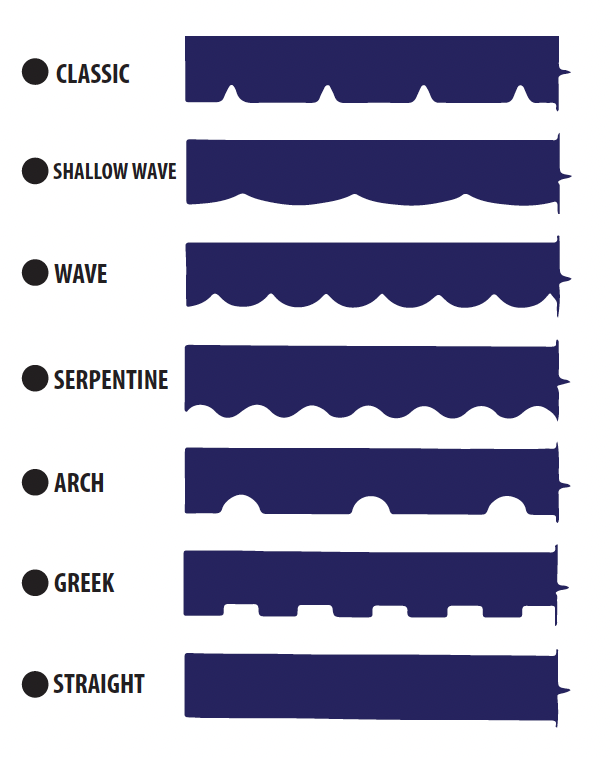

Lastly, let’s dive into whether or not your awning gets a rigid valance or a soft valance.

Rigid Awning Valance: A rigid awning valance is achieved by pulling the fabric down the face of the valance and around the bottom bar, then tightening with lacing on the back side. It is designed to maintain a fixed shape without anything blowing in the wind. The advantage of a straight or rigid valance is that nothing is blowing with the wind and it provided a clean, sleek design.

Soft valances are commonly used in residential settings and can offer a more relaxed, casual, or decorative look. They can be customized with various colors, patterns, or scalloped designs to match the overall style of the outdoor space. The possible disadvantage of a soft valance is that in windy conditions they can be a bit noisy and the fabric can tend to get fatigued and fail in corners where fabric is rubbing against the frame.

The most common soft valance designs include:

1. Classic2. Shallow Wave3. Wave4. Serpentine5. Arch6. Greek7. Straight(Seen below)

The choice between a rigid awning valance and a soft valance depends on personal preference, the desired aesthetic, and the intended use of the awning. Rigid valances may be preferred for a sleeker and simple appearance, while soft valances can provide a softer and more customizable look.All said and done, Custom Canvas Structures, Inc. is dedicated to giving the customer the longest-lasting, best-looking awnings available. We know that one of the best ways to build a long-term relationship with a customer is to give them a product and service that they can depend on and trust. A large portion of our work is repeat customers which is an estimate in itself that we are on the right track.

Thank you for spending a few minutes preparing for your awing appointment. We look forward to meeting you and most of all the opportunity to call you, our customer.